B3001 SERIES

Product Description

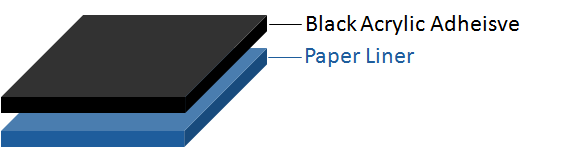

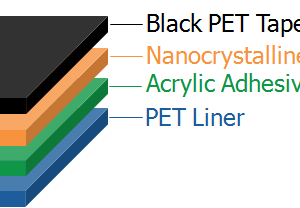

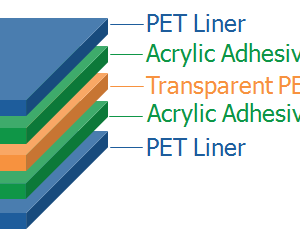

B3001 Series tape features a specially structured black acrylic adhesive layer without carrier and is waterproof. The special structure can provide superior impact resistance to meet drop and puncture testing as well as excellent die-cutting performance.

Features

✔ High Bond Strength

✔ Waterproof

✔ Easy Die-Cut

✔ RoHS Compliant & Halogen Free

Applications

B3001 Series tape can be used in a wide range of electronic components bonding such as lens bonding and LCM attachment along with other bonding applications where impact resistance, high strength and waterproof bonding are needed.

Typical Properties

| Part Number | B3001-015 | B3001-020 | B3001-025 | B3001-030 | B3001-040 | Test Method |

| Available Thickness (mm) | 0.15 | 0.20 | 0.25 | 0.30 | 0.40 | ASTM D3652 |

| Color | Black | – | ||||

| Type of backing | None | – | ||||

| Type of adhesive | Acrylic-based | – | ||||

| 1800 Peel to Steel (g/inch @1hr RT) | 3200 | 3600 | 3900 | 4400 | 5000 | ASTM D3330 |

| 900 Peel to ABS (g/inch @72hrs RT) | 2200 | 2500 | 2900 | 3200 | 3800 | ASTM D3330 |

| 900 Peel to Glass (g/inch @72hrs RT) | 2900 | 3500 | 3700 | 4700 | 5200 | ASTM D3330 |

| 900 Peel to PP (g/inch @72hrs RT) | 1800 | 2100 | 2400 | 2700 | 2900 | ASTM D3330 |

| 900 Peel to PC (g/inch @72hrs RT) | 2400 | 3100 | 3500 | 4100 | 4800 | ASTM D3330 |

| 900 Peel to PMMA (g/inch @72hrs RT) | 2200 | 2600 | 3200 | 3300 | 3800 | ASTM D3330 |

| Waterproof Class | IPX 8 | – | ||||

| Operating Temperature (°C) | -20~120 | – | ||||

| Standard Size (mm x m) | 1200*50 | – | ||||